FRP and PVDF Lining

FRP Lining

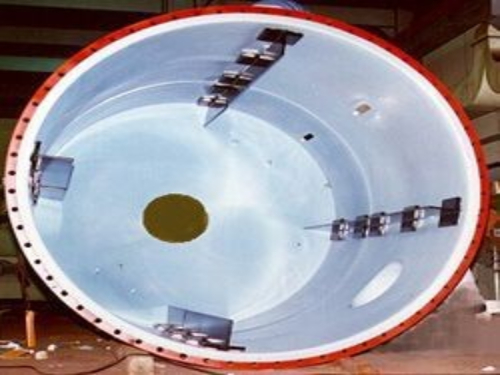

FRP Coatings & Linings (Fiberglass Reinforced Plastics), is a superior coating and lining system formed by thermosetting resins and fiberglass to raise durability and safety by lining inside of piping systems chemical storage tanks, Mobile tanker, cooling towers, and other types of industrial process equipment.

It provides strength and durability and is not affected by structural imperfections, which can occur.After completion of FRP lining, the tank will have the same strength as the FRP coated tank that is installed to the inside.

In a lot of applications, FRP coating provides superior performance over other materials. When a polyester resin is used in combination with fiberglass, the lining lifetime becomes longer and becomes much more corrosion resistant.

The material is a room-temperature-curing type and applicable for on-site lining and large-sized tanks.

FRP has several advantages that make it perfect for the unfriendly and hostile conditions of an industrial environment: weatherproof, non-corrosive, impact resistant and fire retardant. FRP is also resistant to chemicals (free from acidic, environmental and alkaline corrosion). That is why tanks that are used to store chemicals are lined with FRP.

PVDF LINING

PVDF coatings are one of the most common types of industrial coatings in use today. This type of coating is created by polymerizing vinylidenedifluoride. It’s a specialty plastic that belongs to the family of fluoropolymers and is used in applications that require high levels of purity and strength, as well as those that require excellent resistance to acids, solvents, bases, and heat. PVDF has a fairly low melting point, which can be beneficial as well in certain applications.