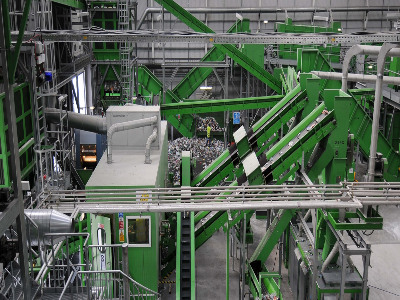

Supply Conveyor Belt

General Industries is the one stop solution provider for complete material handling requirements such as conveyor belting, conveyor belting service and conveyor accessories.

Our partnership with leading global brands gives us the unique advantage of offering our customers the best quality, widest range of products along with the latest developments in the field of conveyor belts; unmatched by any other supplier.

Industries and Applications

We provide comprehensive product ranges for the various requirements of the most different of sectors. And at the same time the guarantee of maximum service life and economical operation.

The following sections will show you what GI has to offer for your industry.

General Purpose

The design of general purpose conveyor belts enables application in all areas of materials handling. Due to the carcass construction and quality of cover, these belts are noted for their reliability and long life in all industrial applications, either for general purposes or handling of sharp-edged and extremely abrasive materials

General purpose conveyor belts are suitable for:

• Sand, Gravel, Stone industry

• Cement, Concrete plants

• Heating and Power stations, Garbage incineration plants

• Road construction machinery

• Recycling, Compost industry, Mineral processing plants

• Timber industry and Sawmills

• Slag conveyors

• REA-gypsum

• Broken glass

• Silica sand or materials containing silica sand

• Clay and argil

Fire Retardant BELTING

Conveyor belt fires can present a serious hazard in the confined environment of an underground coal mine or environments where coal dust, coke, sulphur or other potentially combustible materials are involved, the conveyor belt must not be allowed to create static electricity that could ignite the atmosphere. GI provides special types of fire and flame resistant rubber conforming to the various standards (i.e ISO 340, DIN – K, CAN CSA – C, MSHA, etc.) to raise safety to the highest degree for the above applications.

FIRE and FLAME RESISTANT conveyor belts are suitable for:

• Heating stations, Power stations and garbage incinerating plants

• Coal loading, coal transportation

• Steelworks and foundries

• Closed conveyors

• Flammable goods

• Potentially explosive areas

• Near flame sources

• Tunnel constructions

• Underground mines

OIL and GREASE RESISTANT

Oils and greases have a very destructive impact on rubber, however, materials that contain oil or grease are daily conveyed. In order to protect the rubber in the conveyor belt from swelling, different types of rubber that are resistant to oil and grease are applied. Since not all oil and grease types are equally aggressive, GI provides different grades of oil & grease resistant belts to meet various

applications.

OIL and GREASE RESISTANT conveyor belts are suitable for:

• Concrete plants

• Recycling and mineral processing plants, Waste sorting and compost machines

• Metal processing industry, scrap recycling

• Timber industry and sawmills

• Excreta and sewage sludge conveying

• Corn, rape and soilages conveying

• Paper industry

• Fertilizers handling

HEAT RESISTANT

Heat resistant conveyor belts are well-suited for heat resistance applications, where the temperature of conveyed materials is above 90°C, they are mainly used in for conveying Sintered ore, Hot Cement, Hot Powder, Coke, Hot Chemicals, Fertilizers, Clinker & Phosphate etc. GI provides different grades of HR belts that correspond to different temperature conditions.

HEAT RESISTANT conveyor belts are suitable for:

• Cement plants

• Heating stations, Power stations, Garbage incineration plants

• Chemical industry

• Steelworks, metal foundries, metal processing industry

• Hot asphalt transportation

ELEVATOR BELT (Side Wall / Bucket Elevator)

ELEVATOR conveyor belts are used where the application demands lifting of the conveyed material within a confined space at very steep angles as high as 900 degrees.

The latest development in steep angle conveying is the Side Wall Conveyor belt, which can be used in places where space is a constrain and can effective negotiate turning through any angle up to a vertical line and back to the horizontal.

ELEVATOR conveyor belts are suitable for:

• Sand, gravel and stone industry

• Cement, concrete plants

• Heating stations, power stations, garbage incinerating plants

• Asphalt mixing plants

• Recycling, compost, mineral processing plants

• Timber industry and sawmills

• Farming

• Warehousing, silo feeding

• Docks, ship loading and unloading

• Sugar refineries, salt mines, potatoes and starch factories

• Foundries

• Waste treatment plants

SLIDING

For technical reasons, a rotating supporting roller cannot be installed in certain types of conveyors, therefore, a belt requires the so-called sliding table to operate. Such operation does not allow the bottom surface of the belt to be coated with rubber, as this would increase friction between the base and the belt. GI provides special sliding conveyor belts where friction is decreased to a minimum.

SLIDING conveyor belts are suitable for:

• Timber industry and sawmills

• Recycling, garbage and mineral processing plants

• Packaging industry

• Airports

• Parcel terminals and cardboard plants

• Food industry

CHEVRON

Standard Conveyor belts with a smooth carrying surface are useful for conveying of material up to the angle of inclination 18° as an upper limit.

CHEVRON belts are the right belts to meet the application when higher angles of inclination are required and can achieve up to 40° angle of inclination. Chevron belts are specifically designed to prevent load slippage or roll back of products while conveying and comes with cleats that are integrally molded with top cover rubber that prevents separation from belt.

CHEVRON conveyor belts are suitable for:

• Quarries, sandpits

• Cement works, lime works

• Farming: conveying of beets, grains, potatoes, fertilizers, wooden chips

• Coal and coke transport

• Sugar refineries

• Salt mines

• Mobile crushers and screens

• Road milling machines

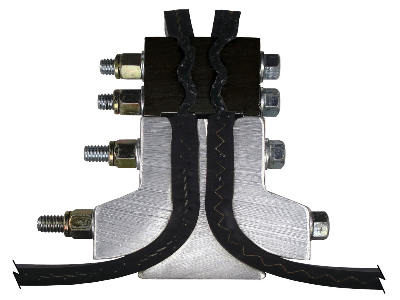

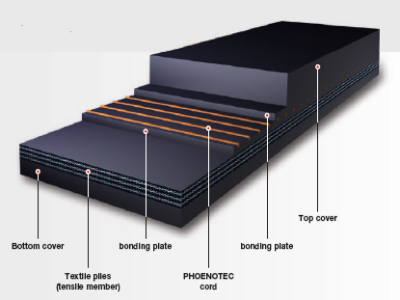

Fabric Reinforced Conveyor Belt

Fabric conveyor belts, or textile conveyor belts as they are also called, are used principally for heavy-duty, abrasive materials.

Fabric conveyor belts are suitable for:

• Steel and foundry

• Coal and prep plants

• Hard rock mining

• Package handling

• Baggage handling

• Grain handling

• Sand and gravel

• Pulp and paper

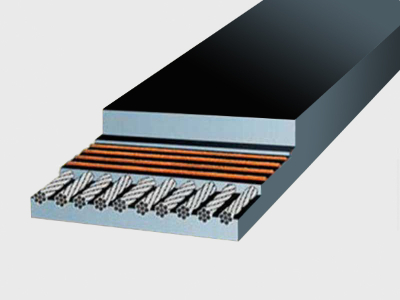

Steel Cord Reinforced Conveyor Belt

Steel cord conveyor belts are highly wear-resistant and used principally for long-haul conveying, heavy loads and physically demanding applications. They are especially suitable for high-mass or high-volume flows and for abrasive materials.

Steel Cord conveyor belts are suitable for:

• Underground mining

• Open-pit mining

• Steel plants

• Power plants

• Stone quarries

• Tunnelling

• Ports